If you need to deliver your products frequently, a chance that you know how high-quality and attractive packaging should be. During the designing stage, you will come across the term ‘dieline.’ It is an essential aspect of print and packaging design as it guides the production process. Additionally, it ensures the final product meets the exact specifications of the design. But do you know how important this aspect is? Well then, let’s explore more about dieline and its importance in the print and packaging industry!

A Brief Intro to a Dieline

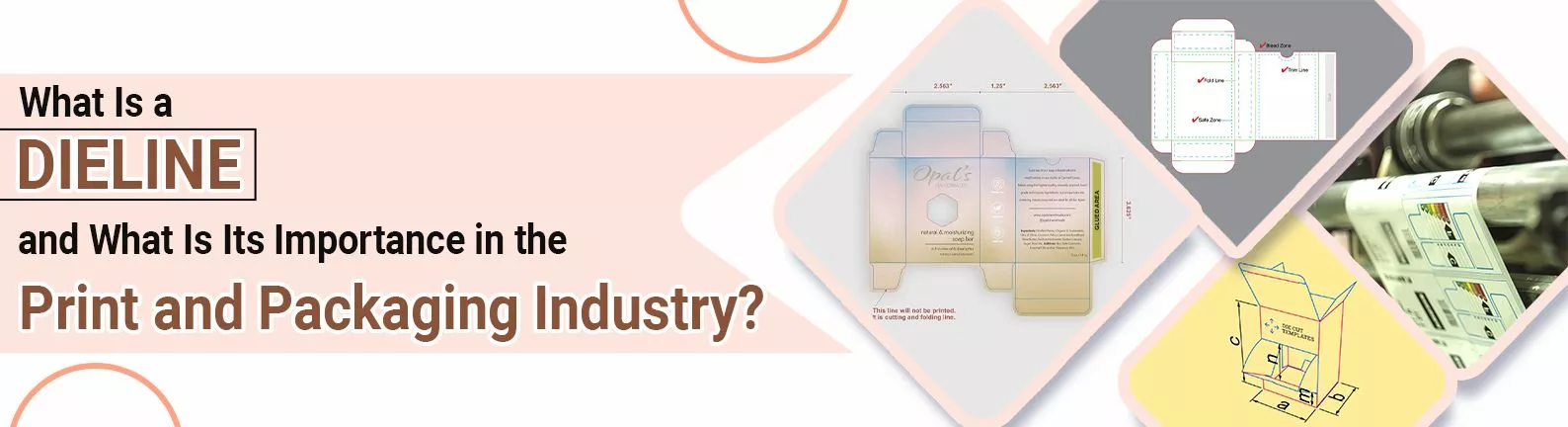

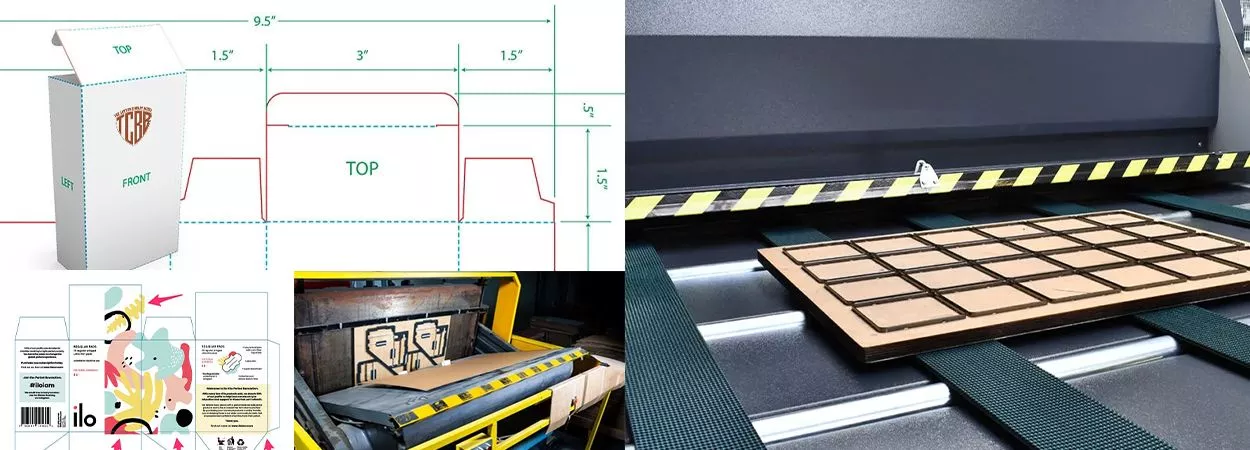

A dieline is a blueprint or a two-dimensional outline. This outline represents the final shape and size of a printed piece or product packaging. It is created using specialized software such as Adobe Illustrator. This aspect allows designers to create an outline of the product they are designing.

When Did the Packaging Industry Start Using Dielines?

The use of dielines in the packaging industry dates back to the mid-20th century. Before dieline, the packaging design was created manually. Yes, we are talking about redrawing each design for every new product. Hence, we can imagine how time-consuming and expensive the process was.

A machine called a pantograph was developed in the early 1950s. This machine has the capability to trace and copy designs onto cardboard. This allowed for the creation of a master template. Then, a master template is used to create multiple identical designs. This was the beginning of the dieline, which is essentially a digital version of the master template.

With the development of computer-aided design (CAD) software in the 1980s, dielines became even more precise. In fact, it enables you to create more complex designs and better efficiency in the production process. Today, this technique ends up being an essential part of packaging design and production. Yes, it helps to ensure accuracy, efficiency, and consistency in the manufacturing process. Given the advancements in packaging design, understanding the concept of 3D packaging has become increasingly relevant.

The Importance of Dielines in the Print and Packaging Industry

We can explore the importance of dielines in the print and packaging industry in huge aspects. The dieline process even turns out to be the most important technique. How?

Because it makes high-quality packaging for various industries.

Have a look below for the importance of dielines!

Accuracy in Production

Yes, the dieline technique ensures accuracy in production. How?

It provides comprehensive information to the printer. This includes the final product’s shape and size, the position of design elements, and any special finishes essential. This way, it reduces the chances of errors. As a result, it ensures that the final product meets all your specifications.

Let’s know more about this!

- Guarantees proper alignment

This technique ensures that all your design elements will be properly aligned. This will help a lot to avoid any design elements being accidentally cut off in the production process.

- Helps in precision cutting

With the help of this technique, any printer can precisely cut the material to the exact shape and size. This ensures that your product packaging will be of excellent quality and consistency.

- It provides easy-to-follow instructions for the printer

Yes, a dieline will provide easy-to-follow instructions for the printer. This will reduce the chances of misunderstandings or errors throughout the production process.

- It helps in quality control

A dieline technique provides complete specifications about the desired product. This way, it will be valuable to maintain high standards of quality control. As a result, it ensures that the final packaging meets your expectations. Of course, it will make sure that your packaging is of superior quality.

It Facilitates Cost-Effective Production

With an innovative dieline, a printer can produce your custom packaging with minimal waste of materials. This not only saves money. Far better, it also reduces the environmental impact of the printing process.

Let’s explain this further!

- Efficient use of materials

Yes, this technique will help you optimize the use of materials. How?

By confirming that your packaging design will fit within a set area.

This will, as a result, reduce waste. Plus, you can also save any unused material for future use.

- Offers lower production costs

A dieline process offers lower production costs. The process will reduce the time and effort to create your packaging. A dieline provides precise specifications and instructions. Thus, packaging companies can produce custom packaging with minimal waste and at a faster rate.

- Improves efficiency

With its help, printers can easily understand the design requirements. Thus, they can start production quickly without any further design revisions. This helps to improve the efficiency of the production process. Ultimately, this will surely help you save time and money.

- Reduces environmental impact

Yes, a dieline reduces the environmental impact of the production process. How?

By minimizing the amount of waste generated.

Accordingly, by optimizing the use of materials, less material will end up in landfills. This will surely be better for the environment.

Consistent Branding

Another importance of dielines in the print and packaging industry is that it ensures consistent branding across all packaging. By following the same dieline for different products, a brand can maintain its unique identity. Well, we know that a unique identity is essential for building brand recognition and loyalty.

So, here is how a dieline contributes to consistent branding!

- Maintains brand identity

By using a consistent dieline for all packaging, a brand can maintain its unique identity. This helps to create brand recognition. Better yet, it makes it easier for customers to identify the brand.

- Helps you get consistency across products

This method ensures that all your packaging will have a consistent look and feel in the end.

- It makes it easier to customize your packaging

With the help of a dieline technique, you can easily customize your product packaging. Yes, this simply means that you are free to change the colors, fonts, and other elements of your design.

- Shapes a professional brand image

Consistent branding through the use of a dieline helps to create a professional image for your brand. It shows that your brand pays attention to the details and takes pride in your products. This can eventually help to build customer trust and loyalty.

Time-Saving

Last but not least, a dieline can help to save time in the production process. How?

With this technique, a printer can quickly understand the design requirements. Additionally, once the dieline is approved, they can begin production without any further design revisions.

In the end, using a dieline will help a lot in some ways to save more time!

- Faster production

This efficient method helps the printers to quickly start production. In fact, it needs no additional design revisions. This way, you can speed up the production process within a brief time.

- Provides clear and concise instructions to the printer

Yes, a dieline technique provides all clear and concise instructions to the printer. This will minimize the need for back-and-forth communication between the designer and the printer. Hence, it will help you save more time and effort.

- It accommodates consistent production

A dieline method allows you to repeat the same design. Far better, it will reduce the chances of errors throughout the production process.

- Simplifies the workflow

A dieline helps to simplify the workflow by providing a clear roadmap for the production process. This will surely help in reducing confusion and delays. In the end, it will save time and increase productivity.

How to Tell a Difference Between Packaging with a Dieline and One Without a Dieline?

Packaging with a dieline will typically have more precise and uniform cuts and folds. Plus, it will come with an overall construction than packaging without a dieline.

Below are some differences you may notice!

- Accuracy of cuts

Packaging with a dieline will have precise cuts, with clean and sharp edges. On the other hand, packaging without a dieline might have uneven cuts, which indicates that it was not cut to the exact specifications.

- Uniformity of folds

Packaging with a dieline will have uniform and precise folds. This means you will see a crisp and elegant appearance. Meanwhile, without using a dieline, packaging might have uneven folds, which can create an unprofessional look.

- Alignment of design elements

By using a dieline, packaging will have design elements that are properly aligned and positioned. Without it, the design elements will be improperly positioned due to inaccurate cutting.

- Consistency across products

A dieline ensures consistent quality and appearance across all product packaging. Without it, the packaging will have inconsistent quality and appearance. The reason is the fact that each packaging is produced without a set template to follow.

In brief, packaging with a dieline will typically be more precise with consistent cuts and folds. Additionally, it will have the exact alignment of design elements. These differences can impact the overall quality and appearance of your product packaging.

Wrapping Up

Without any doubt, a dieline is an essential aspect of packaging design and style. It provides accurate information about the final product’s shape and size, reduces waste, and ensures consistent branding. Even better, it will save time and money in the production process. When you use this innovative technique, you can create high-quality packaging that meets your exact specifications. To learn better about implementing a dieline into your packaging design, you can contact The Custom Bakery Boxes anytime!