Offset printing is commonly used to produce high-quality prints in bulk quantities. This technique is traditional and has been used for decades. Offset printing process is budget friendly. Therefore, many printing industries are using it. This printing process is also popular because of its versatility.

This comprehensive blog guide mainly consists of what is offset printing and how it works. Moreover, we’ll also discuss its numerous benefits for printing different types of boxes.

This printing method is beneficial for producing high quality images with sharp and vibrant CMYK colors. Further, colors are long lasting and are resistant to fading. Because of this, offset printing is ideal for packaging materials.

More interestingly, this blog is going to enhance your knowledge of printing techniques. So keep reading below and explore the world of offset printing.

What is Offset Printing?

Did you know that offset printing is also known as “offset lithography”?

It is a popular method to print images on large scale. It has process of transferring images from metal plates to rubber blankets or rollers. And then onto the printing material. In this printing technique, paper doesn’t directly touch the metal plates. Because of this, lifespan of plates would increase.

Moreover, the flexible rubber easily adapts different printing surfaces like canvas, cloth, or wood. Therefore, it is highly recommended for rough-surfaced printing material. Offset printing is the main source of consistent and high-quality images. It is beneficial for both types of printing projects. Like small or large scales.

Types of Offset Printing Machines

Offset printing machines are divided into two types. First is sheet-fed offset and second is web offset printing. In web offset printing press, larger and faster machines are used. These machines consist of large rolls of paper and pages. Once the printing has been done, pages are trimmed with a sharp blade.

On the other hand, sheet-fed offset printing is suitable for smaller and medium-sized projects. This technique is beneficial for printing of limited-edition books. Furthermore, web offset printing is not so expensive. You can use them for high-volume publications with frequently changing content. Like metropolitan newspapers.

How Offset Printing Works?

Offset printing is one of the most common image reproduction methods of the modern age. But everyone wants to know how it works.

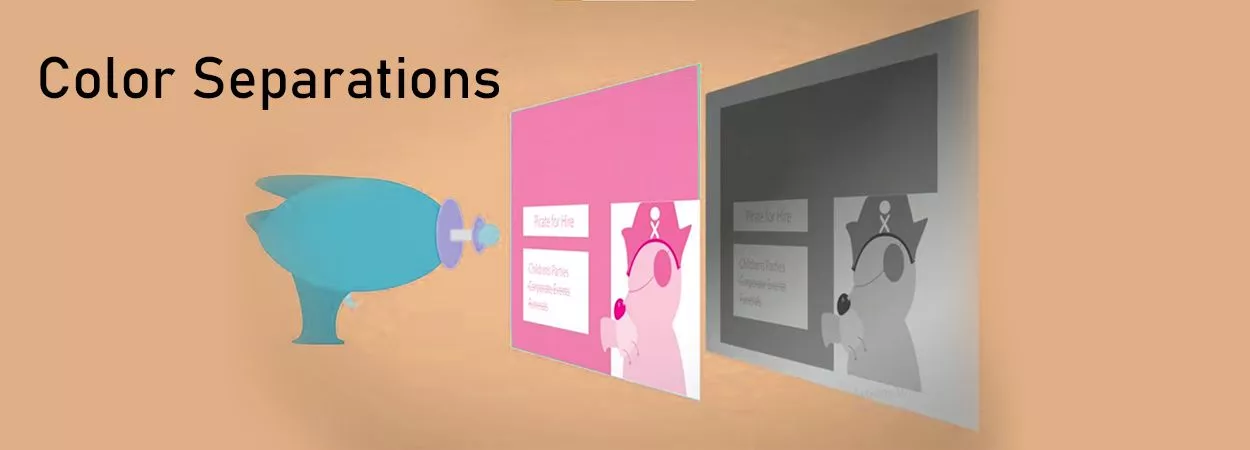

1: Pre-Press Preparation: Breaking Down the Digital Image

The process begins with the pre-press stage. At this stage, digital image is broken down by their color separations. And each color separation transferred on an aluminum plate with the help of a laser machine. Next, a skilled worker loads each plate onto a roller.

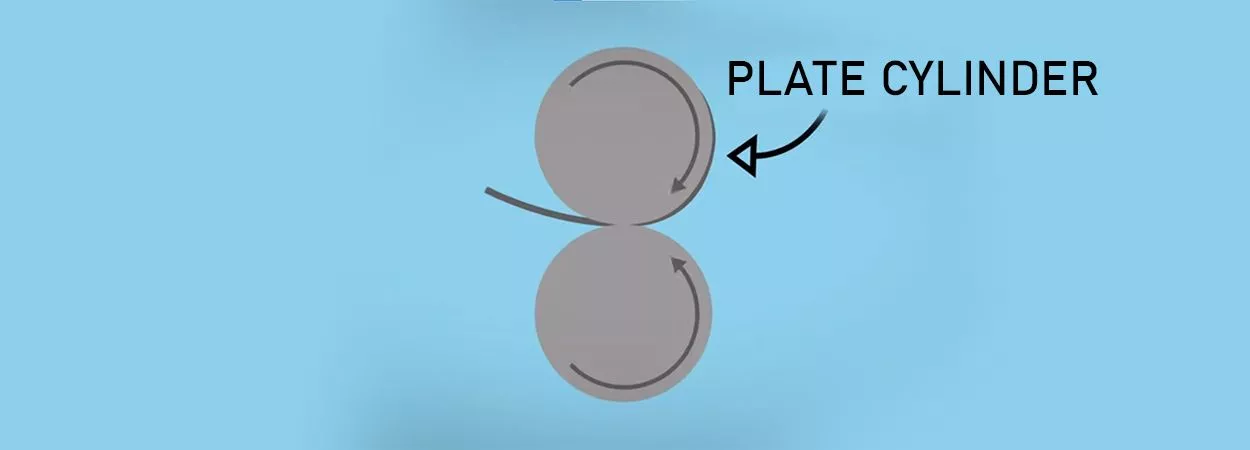

2: Plate Cylinder: Transferring Color Separations

The first roller in offset printing is known as “Plate” cylinder. Basically, it’s a thin cylinder and an aluminum or plastic plate rolls over it. Each plate has the specific text or images that you want to print on the paper. Prepare the plate cylinder in advance to attract ink and repel water. As the plate cylinder rotates, it comes into contact with rollers that apply ink and water.

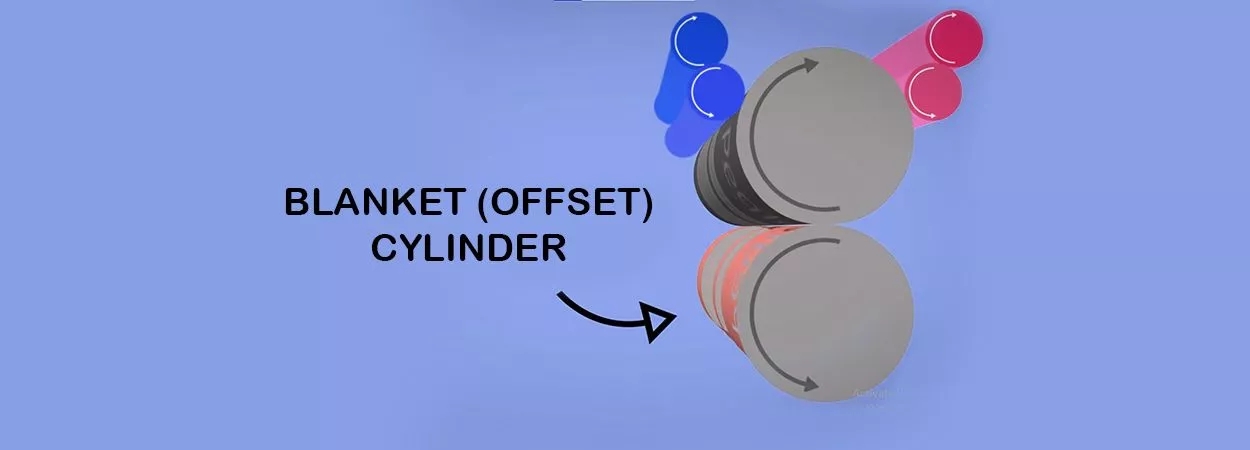

3: Offset Blanket Cylinder: Creating the Ink Design

The next cylinder in the offset printing press is known as “offset blanket” cylinder. It usually has a rubber blanket over it. Moreover, it rotates in the opposite direction to the plate cylinder. As these cylinders roll against each other, water is squeezed out. And ink is transferred onto the rubber blanket. In this way, we get a mirror image of the ink design.

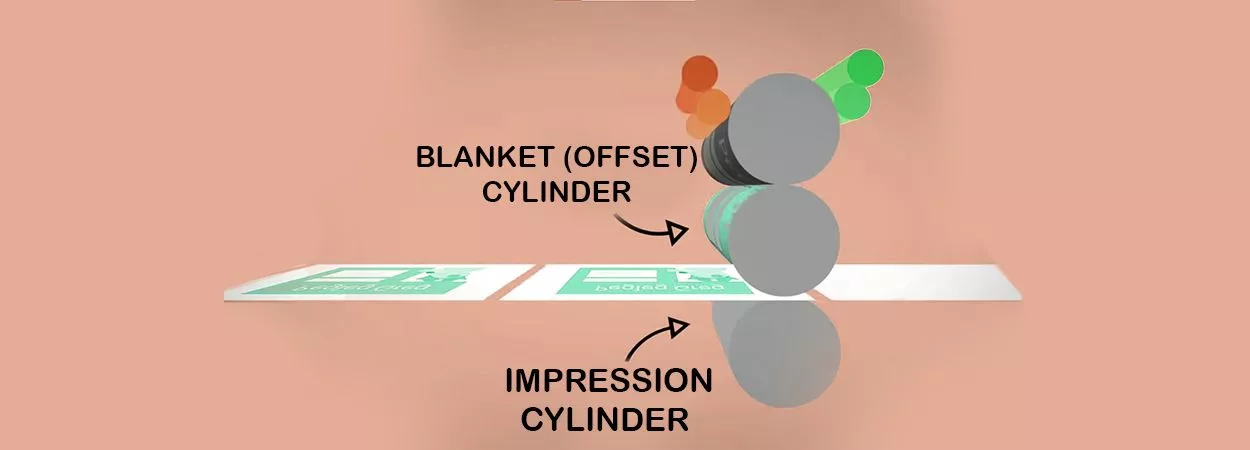

4: Impression Cylinder: Transferring Ink onto Paper

The “impression” cylinder is the third one in the offset lithography process. It is made with clean steel. Further, it rotates in the opposite direction to the blanket cylinder. At this stage, the impression cylinder transfers the ink by pressing paper against the rubber blanket.

Offset printing press is well known for its speed and efficiency. In addition to this, it has the capacity to print 18,000 sheets per hour. And each sheet consists of 48 pages of A4 or letter size. Further, by using offset printing technique you can print approximately 120,000 pages per hour. That is a very impressive output from any printing press. So that if you want to print custom food boxes in large quantities, utilize offset technique.

Offset Printing vs. Digital Printing

Offset printing will give you better results at cheap prices. But we know that every printing project is not in bulk quantity. Some people require a few prints like 500 pages or even less. In that case, digital printing is the optimal solution for you.

Advantages of Digital Printing

- Best for a few printing pages like 1 to 500.

- Automatic colors separation.

- Print any kind of data like numbers, names, and addresses. Modify each of them easily.

- It does not involve the creation of initial plates. So no initial cost.

- Quick turnaround

- Environment Friendly

Advantages of Offset Printing

- It is less expensive for bulk printing jobs

- You can get cheaper price per page if you have more pages to print

- Best for different kinds of paper materials and their custom finishes

- Availability of custom inks like metallic, fluorescent etc

- High quality printing finish with accurate detail and sharp colors

If we talk about commercial point of view then the more you print, the cheaper it gets. After the initial setup cost, you will get the rate of each sheet in just a few cents. Because you have to spend only on paper and ink. Moreover, it is best for large quantities of flyers, brochures, booklets, and newsletters.

Further, using an office printer or a professional digital printer is not the best option. Especially when you have large printing jobs. They are less efficient and more expensive as compared to offset printing. Offset printing produces sharp images & fonts and fine details. Moreover, images are printed with accurate colors. Regular printers cannot achieve this high level of quality.

Offset Printing for Custom Box Printing

Looking for the best method for custom printing for bakery boxes?

Select offset printing press for accurate and high quality results. For instance, if you need custom pizza boxes or custom cake boxes for your packaging needs, use offset lithography. Moreover, you can print high quality logos and designs on almost every kind of packaging box.

Offset printing is an ideal choice for your packaging needs. This technique produces prints that can easily meet your requirements. Additionally, this technique is best for printing designs on different paper materials. Like rigid, cardboard, paperboard, and buxboard.

Is Offset Printing Suitable For Box Printing, And Where To Buy Bakery Packaging?

Of course it is the right choice for your packaging needs. It is cost-effective and versatile in nature. Offset is an ideal choice for producing high-quality prints with sharp images and true colors. Offset printing can tackle any quantity of printing jobs. And it is quite suitable for large quantities.

At The Custom Bakery Boxes, you can find any type of packaging for your business needs. We are also providing offset printing techniques for our valuable customers. Don’t know where to start? Just hit the chat button and get live interaction with our representative. We can solve your packaging requirements from start (designs) to end (final product.)